Development and Performance Evaluation of a Car Brake Bleeding Tool to Reduce Labor and Service Time at PT. UMC Suzuki Ahmad Yani Surabaya

DOI:

https://doi.org/10.21831/jamat.v2i2.2467Keywords:

Development, Maintenance, Braking System, Brake Bleeding, Equipment Manufacturing StagesAbstract

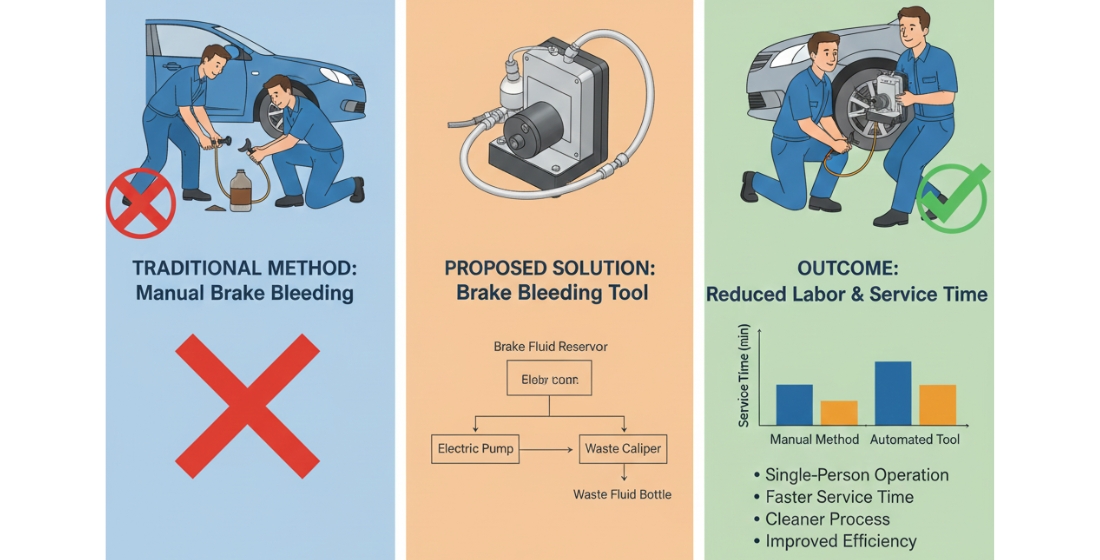

The objectives of this research are: (1) Designing a brake bleeding tool that will be used for the process of bleeding car brakes at the UMC Suzuki Ahmad Yani Surabaya workshop, (2) Knowing the effectiveness of the brake bleeding tool when used at the UMC Suzuki Ahmad Yani Surabaya workshop, (3) Finding out work efficiency after work is carried out using the brake bleeding tool at the UMC Suzuki Ahmad Yani Surabaya workshop. The design of the car brake bleeding tool was developed through analysis, design, development, implementation, and evaluation, resulting in a specialized tool that enhances the mechanic's work at the PT UMC Suzuki Ahmad Yani Surabaya workshop. This tool helps mechanics bleed car brakes, which previously required conventional tools and at least 2-3 additional mechanics. With the developed brake bleeding tool, mechanics only need to work with one person. This tool can also reduce the time required for brake bleeding, which is usually 17 minutes, to just 9 minutes. The development of a brake bleeding tool proved very effective in expediting brake bleeding maintenance at the UMC Suzuki Ahmad Yani Surabaya workshop. With this tool, manual bleeding tools are no longer required, making work more effective without additional labor. This tool produces a time efficiency of 55%. This tool makes the brake bleeding process more accurate and reliable, providing consistent quality assurance and, overall, increasing the productivity and effectiveness of workshop operations.

Downloads

References

[1] A. A. Dzikrullah, Q. Qomaruddin, and M. J. P. S. Khabib, "Analisa Gesekan Pengereman Hidrolis (Rem Cakram) Dan Tromol Pada Kendaraan Roda Empat Dengan Menggunakan Metode Elemen Hingga," pp. 667-678, 2017.

[2] I. N. L. J. L. J. R. B. d. T. Antara, "Analisis Gangguan Sistem Rem Pada Mobil Daihatsu Xenia Serta Penanganannya," vol. 18, no. 1, pp. 20-25, 2018.

[3] H. Abizar and V. J. A. T. J. P. T. O. U. M. P. Vernando, "Analisis Perawatan dan Troubleshooting Sistem Pengereman Pada Mobil Mitsubishi Xpander," vol. 18, no. 1, pp. 20-27, 2023.

[4] N. W. WIDI AYU ARIANI, "AMBANG BATAS KADAR KANDUNGAN AIR DALAM MINYAK REM HIDRAULIK PADA MOBIL BARANG SEBAGAI TOLOK UKUR KELULUSAN UJI KEMAMPUAN REM," POLITEKNIK TRANSPORTASI DARAT BALI, 2023.

[5] J. W. RAMADHANI, "SISTEM PENGENDALIAN INTERN ATAS PROSEDUR PENJUALAN KREDIT (PADA PT SUZUKI UNITED MOTORS CENTRE WARU)," STIESIA SURABAYA, 2019.

[6] R. S. Wijaya and M. J. P. S. Prasetyawati, "Peningkatan Kualitas Pelayanan Guna Meningkatkan Kepuasan Pelanggan Dalam Melakukan Perawatan Kendaraan di AUTO2000 Pramuka Memakai Metode Service Quality," 2021.

[7] D. J. N. I. Yusuf, "Sistem Informasi Perawatan Berkala Pada Mesin Pabrik Berbasis Web," vol. 17, no. 1, pp. 136-143, 2023.

[8] R. Y. Pratama and I. M. J. J. R. M. Arsana, "RANCANG BANGUN ALAT BLEEDING REM SISTEM TERTUTUP PADA MOBIL," vol. 5, no. 2, 2019.

[9] K. Ogura and M. L. Kolhe, "Battery technologies for electric vehicles," in Electric Vehicles: Prospects and Challenges: Elsevier, 2017, pp. 139-167.

[10] W. Wanda, M. A. Fala, R. Febriyanto, Y. A. Purwoko, and E. F. J. T. Tarigan, "MENINGKATKATKAN EFEKTIVITAS PROSES BLEEDING SISTEM REM DENGAN SST BRAKE BLEEDER DI PT XYZ," vol. 15, no. 2, 2024.

[11] K. Anafi, I. Wiryokusumo, I. P. J. J. E. Leksono, and development, "Pengembangan media pembelajaran model ADDIE menggunakan software Unity 3D," vol. 9, no. 4, pp. 433-438, 2021.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Automotive and Mechanical Applied Technology

This work is licensed under a Creative Commons Attribution 4.0 International License.

This journal is an open-access article distributed under the terms and conditions of the Creative Commons Attribution 4.0 International License (CC BY 4.0).

You are free to: Share (copy and redistribute the material in any medium or format) and Adapt (remix, transform, and build upon the material) for any purpose, even commercially, provided you give appropriate credit to the original author(s) and the source.