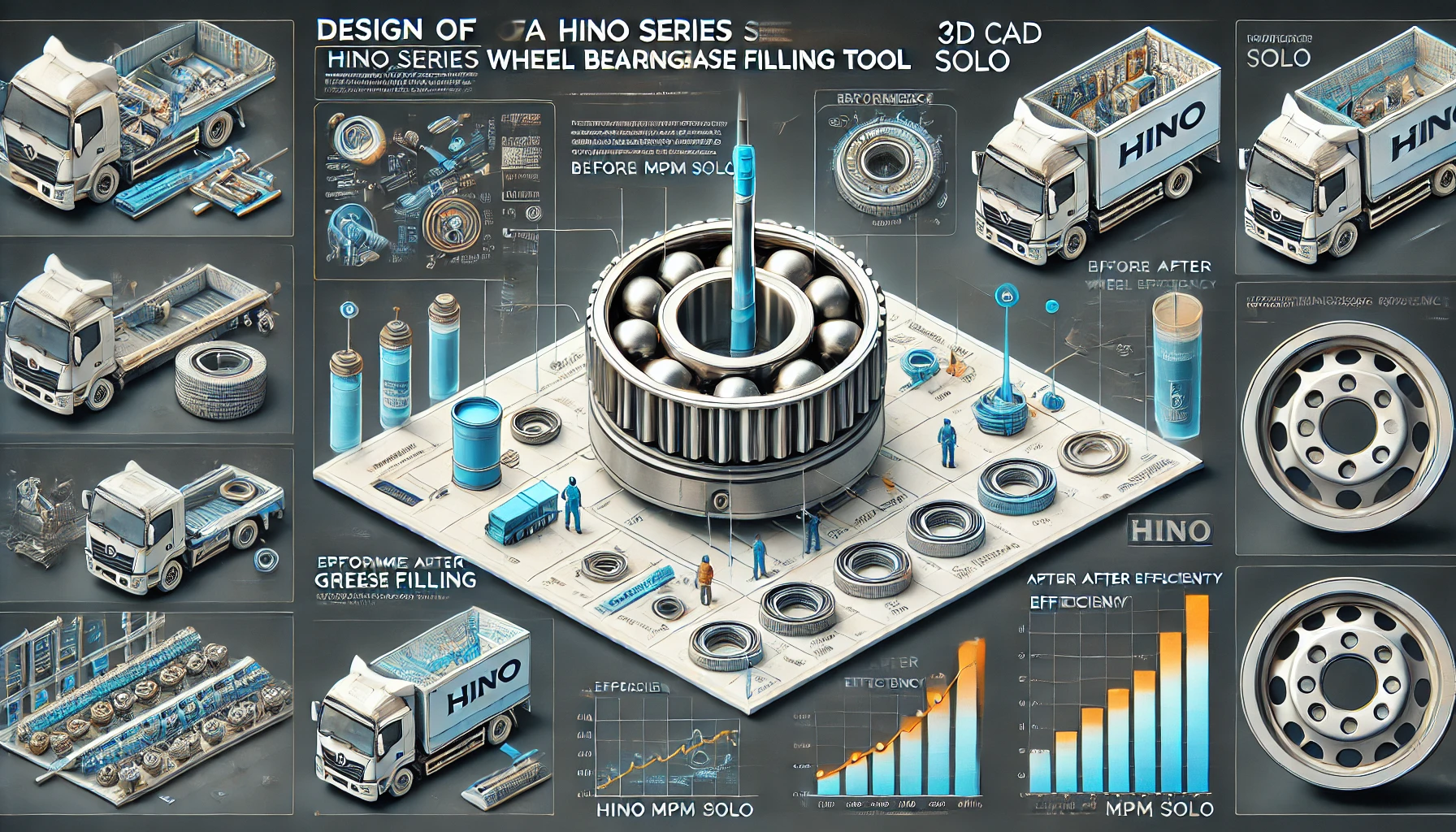

Design of Hino Series Wheel Bearing Grease Filling Tool to Improve Efficiency Performance at Hino MPM Solo

DOI:

https://doi.org/10.21831/jamat.v1i1.814Keywords:

improvement, Spare part, Class based storage, 5S methodAbstract

Efficiency in the vehicle maintenance process is a major concern considering that it can have an impact on saving time, improving accuracy and minimizing operational costs. The use of innovative tools is expected to increase efficiency in the vehicle maintenance process. The current manual lubricant filling process proves to be time-consuming, requires extra labor, and is prone to inconsistency, which can lead to bearing damage.

This research focuses on the design and manufacture of a lubricant filling tool for wheel hub bearings on Hino Series vehicles, which aims to improve maintenance efficiency at Hino Mitra Pratama Mobilindo Solo. The tool is designed using the ADDIE model, which includes needs analysis, design, development, and testing stages. The tool consists of a frame, arm holder, lubricator housing, and pressure plate, all of which are designed to ensure proper lubrication and minimize contamination. Tests show that the tool significantly reduces lubricant filling time, with a 418% increase in efficiency compared to the manual method. It also delivers more consistent results, improving work efficiency and productivity.

Downloads

References

[1] J. Nagy and I. Lakatos, “Predictive Maintenance and Predictive Repair of Road Vehicles—Opportunities, Limitations and Practical Applications,” in SMTS 2024, Basel Switzerland: MDPI, Nov. 2024, p. 27. doi: 10.3390/engproc2024079027.

[2] Q. Gong, L. Yang, Y. Li, and B. Xue, “Dynamic Preventive Maintenance Optimization of Subway Vehicle Traction System Considering Stages,” Applied Sciences (Switzerland), vol. 12, no. 17, Sep. 2022, doi: 10.3390/app12178617.

[3] Y. Liu, Y. Tang, P. Wang, X. Song, and M. Wen, “Reliability-Centered Preventive Maintenance Optimization for a Single-Component Mechanical Equipment,” Symmetry (Basel), vol. 16, no. 1, Jan. 2024, doi: 10.3390/sym16010016.

[4] J. C. Tu, X. Zhang, and X. Y. Zhang, “Basic courses of design major based on the addie model: Shed light on response to social trends and needs,” Sustainability (Switzerland), vol. 13, no. 8, Apr. 2021, doi: 10.3390/su13084414.

[5] N. Aldoobie, “ADDIE Model,” 2015. [Online]. Available: www.aijcrnet.com

[6] L. M. . Uhlaner, The use of the Guttman scale in development of a family business index. EIM Business and Policy Research, 2002.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Journal of Automotive and Mechanical Applied Technology

This work is licensed under a Creative Commons Attribution 4.0 International License.