Engineering Design and Performance Evaluation of a Transmission System for the UG 24 Urban Energy Vehicle

DOI:

https://doi.org/10.21831/jamat.v2i1.1779Keywords:

Transmission System, Energy-Efficient Vehicle, Student Innovation, 4D Method, Custom DesignAbstract

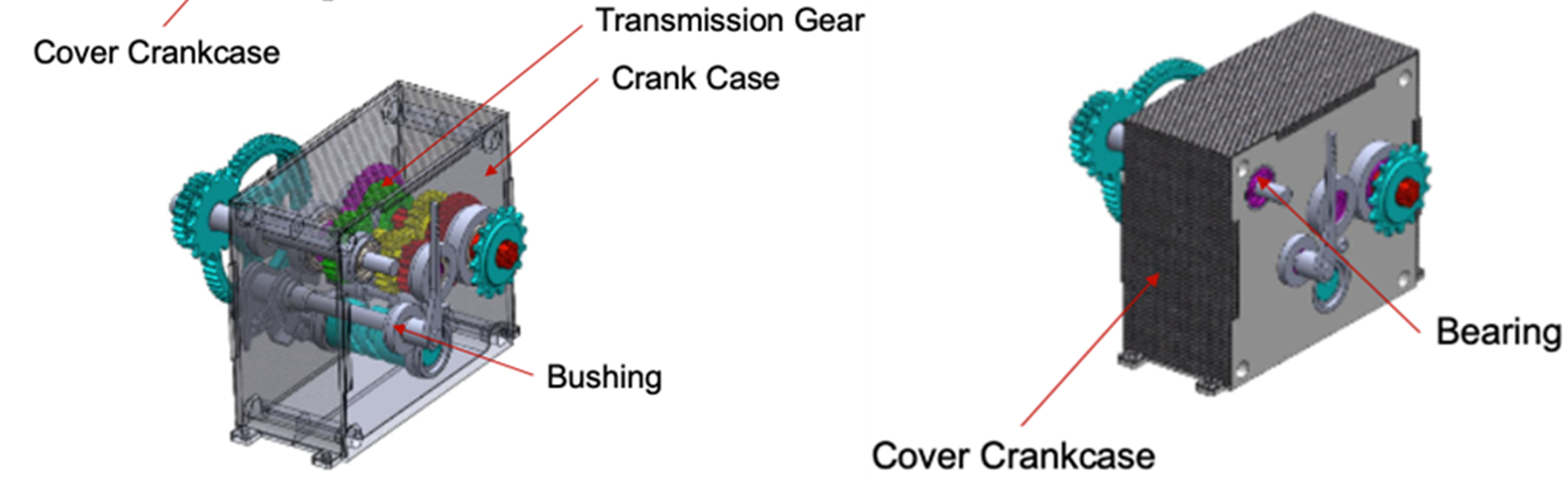

The development of energy-efficient vehicles in student competitions encourages innovation in lightweight and high-performance automotive systems. The Garuda UNY Team, representing Universitas Negeri Yogyakarta, has been actively involved in national competitions such as the Kontes Mobil Hemat Energi (KMHE). In recent evaluations, the team identified a critical weakness in their vehicle's drivetrain, specifically the Internal Gear Hub (IGH) used in the UG-24, which failed to withstand engine torque during acceleration, leading to gear slippage and mechanical failure. To address this issue, a new transmission system was designed and manufactured using the 4D development framework: Define, Design, Develop, and Disseminate. The Define phase identified the mismatch between the IGH design and engine torque requirements. In the Design phase, a new gearbox layout was modeled using Autodesk Inventor, incorporating components such as a crankcase, cover, and custom gear ratios. The development phase involved selecting materials, laser cutting, machining, and assembling transmission parts from mild steel and aluminum. Finally, the Dissemination phase consisted of installing the system in the UG-24 vehicle and conducting a performance evaluation through structured interviews with drivers. Evaluation results showed improved gear shifting performance, with a 75% success rate across ten indicators. Despite positive outcomes, some issues, such as shifting resistance and gear engagement noise, were observed. These were linked to cable friction and dog clutch geometry. Design improvements such as optimized routing and chamfering were recommended for future iterations. This research highlights the impact of tailored transmission systems in student-built energy-efficient vehicles. It provides insight into practical, scalable drivetrain solutions.

Downloads

References

[1] G. P. Mustaqim and T. Wahjoedi, "Effectiveness of Student Participation in Campus Organizations," INCOME: Innovation of Economics and Management, vol. 3, no. 3, pp. 29-35, 2024.

[2] K. Haryana, Z. Arifin, I. N. Yoga, N. W. Purnomo, and M. Z. Naresworo, "The effect of tire pressure on car fuel consumption Garuda urban gasoline 19, in the Shell Eco-Marathon competition Asia 2019, Malaysia," 2024, vol. 3145: AIP Publishing, 1 ed., doi: https://doi.org/10.1063/5.0216922.

[3] T. Paul, "Design of chassis, impact attenuator, suspension and aerodynamic systems of a formula SAE car," 2019.

[4] D. C. Barton and J. D. Fieldhouse, Automotive Chassis Engineering. Springer, 2018.

[5] W. Zhang and J. Xu, "Advanced lightweight materials for Automobiles: A review," Materials & Design, vol. 221, p. 110994, 2022, doi: https://doi.org/10.1016/j.matdes.2022.110994.

[6] G. Lechner and H. Naunheimer, Automotive transmissions: fundamentals, selection, design and application. Springer Science & Business Media, 1999.

[7] M. R. Ahssan, M. Ektesabi, and S. Gorji, "Gear ratio optimization along with a novel gearshift scheduling strategy for a two-speed transmission system in electric vehicle," Energies, vol. 13, no. 19, p. 5073, 2020, doi: https://doi.org/10.3390/en13195073.

[8] S. Zhou, J. Liu, C. Li, and B. Wen, "Nonlinear behavior of a spur gear pair transmission system with backlash," Journal of Vibroengineering, vol. 16, no. 8, pp. 3850-3861, 2014.

[9] X. Li, Q. Cao, X. Zhang, and X. Gao, "Research on the influence of backlash and bearing clearance on torsional vibration of pure electric vehicle gear system," International Journal of Vehicle Noise and Vibration, vol. 17, no. 3-4, pp. 273-288, 2021, doi: https://doi.org/10.1504/IJVNV.2021.123435.

[10] R. B. Indaryanti, H. Harsono, S. Sutama, B. Murtiyasa, and B. Soemardjoko, "4D Research and Development Model: Trends, Challenges, and Opportunities Review," Jurnal Kajian Ilmiah, vol. 25, no. 1, pp. 91-98, 2025, doi: https://doi.org/10.31599/na7deq07.

[11] M. V. Zernin, A. V. Mishin, N. N. Rybkin, S. V. Shil'Ko, and T. V. Ryabchenko, "Consideration of the multizone hydrodynamic friction, the misalignment of axes, and the contact compliance of a shaft and a bush of sliding bearings," Journal of Friction and Wear, vol. 38, pp. 242-251, 2017, doi: https://doi.org/10.3103/S1068366617030163.

[12] J. Singh, A. Verma, R. Kunal, A. Balpande, and M. Dhane, "Shifter fork stiffness correlation to gear shift quality," SAE International Journal of Commercial Vehicles, vol. 6, no. 2013-01-2447, pp. 498-509, 2013, doi: https://doi.org/10.4271/2013-01-2447.

[13] W. Luo, G. Liu, and H. Wang, "Study on Anti-backlash Mechanism Used in Precise Transmission: A Review," 2021: Springer, pp. 1449-1470, doi: https://doi.org/10.1007/978-981-16-7381-8_89.

[14] W. Tang, Y. Zhou, H. Zhu, and H. Yang, "The effect of surface texturing on reducing the friction and wear of steel under lubricated sliding contact," Applied surface science, vol. 273, pp. 199-204, 2013, doi: https://doi.org/10.1016/j.apsusc.2013.02.013.

[15] D. T. Jelaska, Gears and gear drives. John Wiley & Sons, 2012.

[16] H. Du, W. Xiong, H. Wang, and Z. Wang, "A review: virtual assembly of flexible cables based on physical modeling," Assembly Automation, vol. 40, no. 2, pp. 293-304, 2020, doi: https://doi.org/10.1108/AA-04-2018-056.

[17] M. Blomgren, "Modeling and control of engaging gears in gearboxes without synchromesh towards specific angles between gear and coupling sleeve," ed, 2019.

[18] E. Garosi, F. Sheikh, and M. Goodarzi, "Ergonomic Interventions in Risk Reduction," 2025, doi: 10.5772/intechopen.1008463.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Automotive and Mechanical Applied Technology

This work is licensed under a Creative Commons Attribution 4.0 International License.