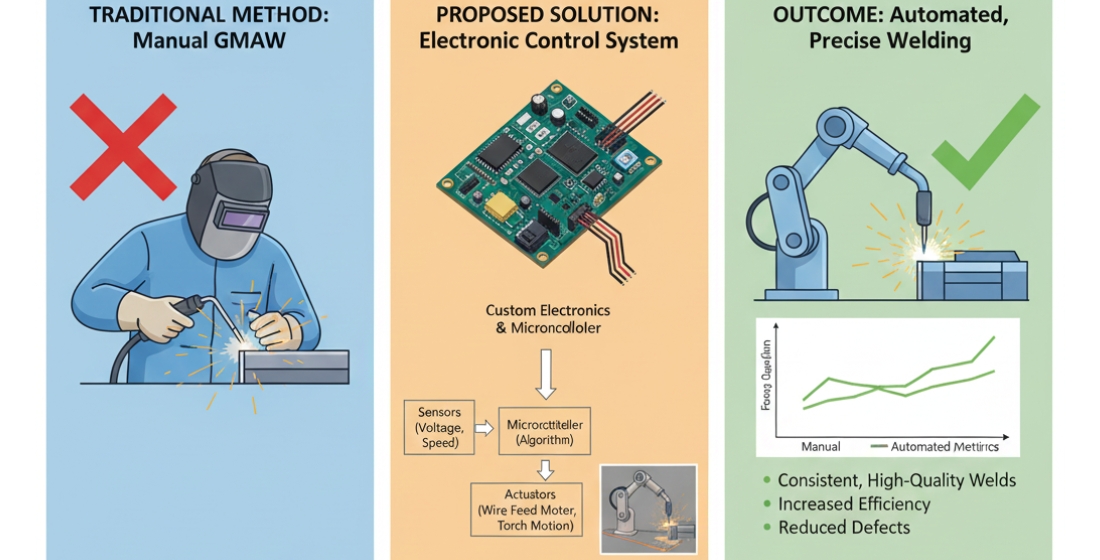

Design of an Electronic Control System for Automating the GMAW Welding Process

DOI:

https://doi.org/10.21831/jamat.v2i2.2465Keywords:

Automation, Control system, GMAW, Travel speedAbstract

This study aims to design and implement an electronic control system to automate the GMAW welding process, focusing on precise regulation of travel speed and travel length to improve repeatability, safety, and weld consistency. The methodology is organized into four stages: (1) needs analysis to define functional requirements, user constraints, and operating ranges; (2) system design covering hardware architecture, sensor and actuator selection, and embedded control logic; (3) implementation through microcontroller-based integration of a motion drive, user interface, and parameter-setting features; and (4) testing to verify accuracy, stability, and performance under realistic operating conditions. The results demonstrate that the system regulates welding speed with an accuracy of 92.54%–99.44%, while maintaining a maximum time standard deviation of 0.038 seconds, indicating stable motion over repeated trials. For welding length control, the system achieves an average absolute error of 0.35–0.5 mm, a percentage error of 0.17%–0.7%, and a standard deviation of 0.051 mm or less, supporting consistent endpoint positioning. In real-world welding tests, the actual weld length deviation ranges from 0.20 to 1.71 mm. It remains within ISO 13920 Class D tolerance limits, confirming practical applicability for general fabrication. The developed controller enables precise parameter control over a speed range of 100–800 mm/min and a length range of 50–300 mm, reducing the need for direct operator intervention and limiting human-induced variability. Overall, the system supports safer, more consistent welding operations and provides a scalable platform for integrating additional monitoring or adaptive control functions. Suitable for training, prototyping, and routine production trials. Future work will address adaptive control diagnostics.

Downloads

References

[1] N. Fonna, Pengembangan revolusi industri 4.0 dalam berbagai bidang. Guepedia, 2019.

[2] D. Mishra, S. K. Pal, and D. Chakravarty, “Industry 4.0 in welding,” in Welding Technology, Springer, 2021, pp. 253–298.

[3] A. Aloraier, A. Albannai, A. Alaskari, M. Alawadhi, and S. Joshi, “TBW technique by varying weld polarities in SMAW as an alternative to PWHT,” International Journal of Pressure Vessels and Piping, vol. 194, p. 104505, 2021, doi: https://doi.org/10.1016/j.ijpvp.2021.104505.

[4] K. Velmurugan, R. Ravisankar, S. Vigneshwaran, K. Karthik, J. Deshwin, and A. Krishana, “Automatic Multi Purpose Welding Device,” International Journal of Engineering Research & Technology (IJERT.ORG), vol. 14, no. 07, Jul. 2025.

[5] S. Puthussery and E. L. Secco, “Design and Integration of a Robotic Welding Parameterized Procedure for Industrial Applications,” Spektrum Industri, vol. 22, no. 1, pp. 60–76, 2024.

[6] H. Nakashima, A. Utsunomiya, J. Takahashi, N. Fujii, and T. Okuno, “Hazard of ultraviolet radiation emitted in gas metal arc welding of mild steel,” J Occup Health, vol. 58, no. 5, pp. 452–459, Sep. 2016, doi: 10.1539/joh.16-0065-OA.

[7] M. A. Rojas Nova, L. M. Calderon Vergel, A. D. Pertuz Comas, and O. Bohorquez Becerra, “Effect of Travel Speed in Arc Welding Processes using the Finite Element Method,” Ciencia en Desarrollo, vol. 12, no. 2, pp. 67–72, 2021.

[8] D. Mishra, S. K. Pal, and D. Chakravarty, “Industry 4.0 in welding,” in Welding Technology, Springer, 2021, pp. 253–298.

[9] J.-M. Lim et al., “Recent Advances in CNC Technology: Toward Autonomous and Sustainable Manufacturing,” International Journal of Precision Engineering and Manufacturing, pp. 1–34, 2025.

[10] S. K. Mohammed, M. H. Arbo, and L. Tingelstad, “Using semantic Geometric Dimensioning and Tolerancing (GD &T) information from STEP AP242 neutral exchange files for robotic applications,” International Journal on Interactive Design and Manufacturing (IJIDeM), vol. 18, no. 9, pp. 6587–6603, 2024.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Journal of Automotive and Mechanical Applied Technology

This work is licensed under a Creative Commons Attribution 4.0 International License.