Implementation of a Camera-Based Inspection System for Measuring the Diameter of 3D Printed Filaments Made from LDPE Water Bottle Caps

Downloads

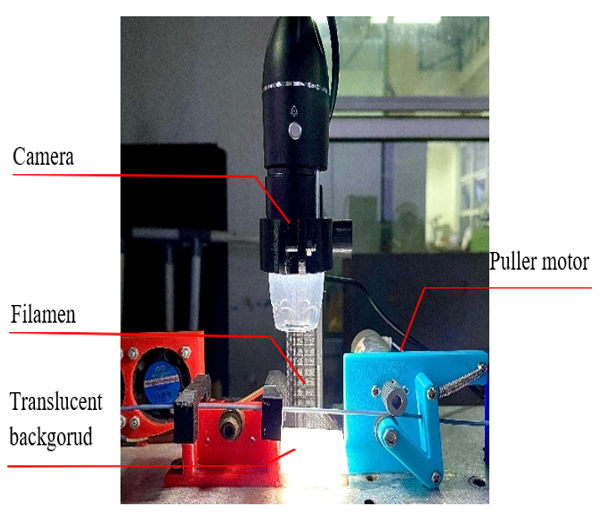

Advances in additive manufacturing technology are driving the need for high-quality, affordable, and sustainable filaments. In Indonesia, the demand for filaments and extruders is largely met through imports, prompting researchers to innovate and develop filament extrusion machines, including those at the Politeknik Manufaktur Bandung, which has developed a filament extrusion machine equipped with a camera-based inspection and control system to produce high-quality filaments from LDPE gallon cap waste. This system integrates a digital microscope camera and a microcontroller to monitor the diameter of the extruded filament and correct the diameter by controlling the speed of the pull motor to stabilize the diameter in real-time. Image processing uses a color-based edge detection algorithm, and camera calibration results show a precision of 0,009 mm/pixel. Diameter data is sent to the Arduino Mega, which then uses the L298N driver to control motor speed via the Sliding Mode Control (SMC) method. Test results show that at 15 RPM, the average filament diameter is 1,77 mm with an error of 1,14%, while at 20 RPM it becomes 1,56 mm with a larger error of 10,86%, compared to the standard commercial filament size of 1,75mm. SMC control also demonstrated better performance than PID in terms of system accuracy in reaching the set point. This system could serve as an economic and ecological solution for local recycled filament production, reducing dependence on imported products.

Downloads

[1] Muslimin et al., ‘Utilization of Recycle LDPE (r‑LDPE) Plastic and Galangal Stem Fiber for the De-velopment of 3D Printing Filaments’, Mater. Sci. Forum, vol. Vol. 1134, pp.125–134, Dec. 2024, doi: 10.4028/p-sf9nRH.

[2] D. Dubey, S. P. Singh, and B. K. Behera, ‘A review on recent advancements in additive manufacturing techniques’, Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng., p. 09544089241275860, Aug. 2024, doi: 10.1177/09544089241275860.

[3] '3D printing and International Trade: What is the evidence to date?’, OECD Trade Policy Papers 256, Nov. 2021. doi: 10.1787/0de14497-en.

[4] K. Yu, Q. Gao, L. Lu, and P. Zhang, ‘A Process Parameter Design Method for Improving the Filament Diameter Accuracy of Extrusion 3D Printing’, Materials, vol. 15, no. 7, p. 2454, Mar. 2022, doi: 10.3390/ma15072454.

[5] ‘Extruder Machine Buyers & Importers in Indonesia - Volza’. Accessed: Jun. 18, 2025. [Online]. Availa-ble: https://www.volza.com/ogimages/buyers/e/extruder-machine-buyers-in-indonesia-buyers.svg

[6] M. L. Sonjaya, M. Mutmainnah, and M. F. Hidayat, ‘Construction of Plastic Waste Extruding Machine to Produce Filaments of 3D Printing Machine’, Int. J. Mech., vol. 16, pp. 82–90, Jul. 2022, doi: 10.46300/9104.2022.16.10.

[7] Y. K. P. Saleh, M. Zaenudin, M. M. Al Azzam, A. K. Bakar, and A. N. Haryudiniarti, ‘Filament maker design for Polyethylene Terephthalate(PET) plastic bottle recycling’, presented at the 2ND INTERNA-TIONAL CONFERENCE SERIES ON SCIENCE, ENGINEERING, AND TECHNOLOGY (ICSSET) 2022, Sidoarjo, Indonesia, 2024, p. 060009. doi: 10.1063/5.0218078.

[8] P. G. C. Nayanathara Thathsarani Pilapitiya and A. S. Ratnayake, ‘The world of plastic waste: A review’, Clean. Mater., vol. 11, p. 100220, Mar. 2024, doi: 10.1016/j.clema.2024.100220.

[9] M. Apriliani, ‘THERMAL TEST OF 3D PRINTING FILAMENTS FROM PLASTIC WASTE AS AN ENVIRONMENTALLY FRIENDLY PRINTING MEDIA ALTERNATIVE’, Kreator, vol. 10, no. 2, pp. 36–39, Feb. 2024, doi: 10.46961/kreator.v10i2.876.

[10] D. P. Da Silva et al., ‘Property mapping of LDPE during 3D printing: evaluating morphological develop-ment with X-ray scattering’, Front. Mech. Eng., vol. 9, p. 1232562, Aug. 2023, doi: 10.3389/fmech.2023.1232562.

[11] Sr Vehicle Integration Engineer, USA, S. Naveen D Surabhi, M. Dolu Surabhi, and Quality Assurance Engineer, USA, ‘Enhancing Dimensional Accuracy in Fused Filament Fabrication: A DOE Approach’, J. Mater. Sci. Manuf. Res., pp. 1–7, Apr. 2024, doi: 10.47363/JMSMR/2024(5)177.

[12] F. Tikhani and P. Hubert, ‘Extrusion optimization and advanced mechanical characterization of fibre-reinforced polycarbonate filaments: Improving performance for fused filament fabrication’, Compos. Part Appl. Sci. Manuf., vol. 191, p. 108752, Apr. 2025, doi: 10.1016/j.compositesa.2025.108752.

[13] R. B. Kristiawan, F. Imaduddin, D. Ariawan, Ubaidillah, and Z. Arifin, ‘A review on the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters’, Open Eng., vol. 11, no. 1, pp. 639–649, Apr. 2021, doi: 10.1515/eng-2021-0063.

[14] R. Badarinath and V. Prabhu, ‘Real-Time Sensing of Output Polymer Flow Temperature and Volumetric Flowrate in Fused Filament Fabrication Process’, Materials, vol. 15, no. 2, p. 618, Jan. 2022, doi: 10.3390/ma15020618.

[15] K. T. Werkle, C. Trage, J. Wolf, and H.-C. Möhring, ‘Generalizable process monitoring for FFF 3D printing with machine vision’, Prod. Eng., vol. 18, no. 3–4, pp. 593–601, Jun. 2024, doi: 10.1007/s11740-023-01234-2.

[16] R. Zende and R. Pawade, ‘A novel IoT based machine vision system for on-machine diameter measure-ment and optimization’, Eng. Res. Express, vol. 5, no. 4, p. 045075, Dec. 2023, doi: 10.1088/2631-8695/ad0c8c.

[17] B. M U, H. Raghuram, and Mohana, ‘Real Time Object Distance and Dimension Measurement using Deep Learning and OpenCV’, in 2023 Third International Conference on Artificial Intelligence and Smart Energy (ICAIS), Coimbatore, India: IEEE, Feb. 2023, pp. 929–932. doi: 10.1109/ICAIS56108.2023.10073888.

[18] A. M. Almawla, M. J. Hussein, and A. T. Abdullah, ‘A Comparative Study of DC Motor Speed Control Techniques Using Fuzzy, SMC and PID’, J. Eur. Systèmes Autom., vol. 57, no. 2, pp. 397–406, Apr. 2024, doi: 10.18280/jesa.570209.

[19] H. Maghfiroh, A. Sujono, M. Ahmad, and C. H. B. Apribowo, ‘Basic Tutorial on Sliding Mode Control in Speed Control of DC-motor’, J. Electr. Electron. Inf. Commun. Technol., vol. 2, no. 1, Apr. 2020, doi: 10.20961/jeeict.2.1.41354.

[20] H. Mohammad Noor, M. Ibrahim, A. A. A. Norazaman, D. Abu Bakar Sidik, R. Mohd Adnan, and N. S. Mohd Aripen, ‘Parameter Optimization in FDM Filament Fabrication via Single Screw Extruder’, Pa-perASIA, vol. 40, no. 4b, pp. 266–272, Aug. 2024, doi: 10.59953/paperasia.v40i4b.203.

[21] M. H. Wankhade and S. G. Bahaley, ‘Design and Development of Plastic Filament Extruder for 3D Print-ing’, IRA-Int. J. Technol. Eng. ISSN 2455-4480, vol. 10, no. 3, p. 23, May 2018, doi: 10.21013/jte.v10.n3.p1.

[22] M. El Mrabet, Z. Mekrini, A. El Mesbahi, and M. Boulaala, ‘Comparative simulation study of electric motors for high performance of 3D printers’, TELKOMNIKA Telecommun. Comput. Electron. Control, vol. 21, no. 4, p. 935, Aug. 2023, doi: 10.12928/telkomnika.v21i4.24210.

[23] W. Fabre, K. Haroun, V. Lorrain, M. Lepecq, and G. Sicard, ‘From Near-Sensor to In-Sensor: A State-of-the-Art Review of Embedded AI Vision Systems’, Sensors, vol. 24, no. 16, p. 5446, Aug. 2024, doi: 10.3390/s24165446.

[24] ‘Optimizing Master-Slave Communication in Collaborative Robotics Using IoT-Enabled Robot Interac-tion’, Indian J. Pure Appl. Phys., 2024, doi: 10.56042/ijpap.v62i11.12403.

[25] Z. Feng, R. Shi, Y. Jiang, Y. Han, Z. Ma, and Y. Ren, ‘A Multiscale Gradient Fusion Method for Color Image Edge Detection Using CBM3D Filtering’, Sensors, vol. 25, no. 7, p. 2031, Mar. 2025, doi: 10.3390/s25072031.

[26] ‘Object size measurement and camera distance evaluation for electronic components using Fixed-Position camera’, Comput. Vis. Stud., 2023, doi: 10.58396/cvs020101.

[27] Y. Tu et al., ‘Dimensional Accuracy Evaluation of Single-Layer Prints in Direct Ink Writing Based on Machine Vision’, Sensors, vol. 25, no. 8, p. 2543, Apr. 2025, doi: 10.3390/s25082543.

[28] M. F. Khan, E. M. A. Dannoun, M. M. Nofal, and M. Mursaleen, ‘Significance of Camera Pixel Error in the Calibration Process of a Robotic Vision System’, Appl. Sci., vol. 12, no. 13, p. 6406, Jun. 2022, doi: 10.3390/app12136406.

[29] J. W. Chan, ‘Sliding Mode Control of Brushless DC Motor Speed Control’, Malays. J. Sci. Adv. Tech-nol., pp. 188–193, Oct. 2022, doi: 10.56532/mjsat.v2i4.57.

[30] E. H. Dursun and A. Durdu, ‘Speed Control of a DC Motor with Variable Load Using Sliding Mode Control’, Int. J. Comput. Electr. Eng., 2016, doi: 10.17706/ijcee.2020.8.3.219-226.

[31] K.-E. Min, J.-W. Jang, J. Shin, C. Kim, and S. Yi, ‘Development of Prediction Method for Dimensional Stability of 3D-Printed Objects’, Appl. Sci., vol. 13, no. 19, p. 11027, Oct. 2023, doi: 10.3390/app131911027.

[32] P. Minetola and A. Giubilini, ‘A preliminary study on multi-material fused filament fabrication of an embedded strain gauge for low-cost real-time monitoring of part strain’, Prog. Addit. Manuf., vol. 9, no. 6, pp. 2273–2290, Dec. 2024, doi: 10.1007/s40964-024-00582-4.

[33] F. Al-Attar, M. Alsamhan, A. Al-Banna, and J. Samuel, ‘Thermal, Mechanical and Rheological Properties of Low Density/Linear Low Density Polyethylene Blend for Packing Application’, J. Mater. Sci. Chem. Eng., vol. 06, no. 01, pp. 32–38, 2018, doi: 10.4236/msce.2018.61005.

[34] M. M. Zagho, M. A. A. AlMaadeed, and K. Majeed, ‘Thermal Properties of TiO2NP/CNT/LDPE Hybrid Nanocomposite Films’, Polymers, vol. 10, no. 11, p. 1270, Nov. 2018, doi: 10.3390/polym10111270.

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

The Authors submitting a manuscript do so on the understanding that if accepted for publication, copyright publishing of the article shall be assigned to Journal.